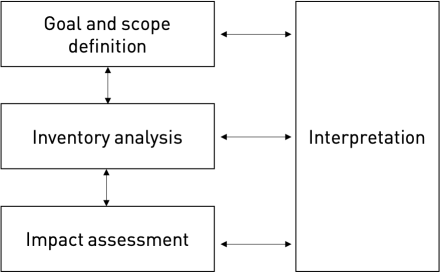

Goal and scope definition

This first step from the LCA is fundamental since it allows the hypothesis to be made explicit. This will enable the results to be interpreted and reinforce their credibility and sincerity.

What are the LCA’s objectives?

A life cycle assessment can serve several purposes. And it is important to define them before carrying out the assessment.

We can differentiate between several sectors of activity:

public, which includes LCAs commissioned by public bodies;

private, which mainly comprises LCAs commissioned by companies, the results of which will be used internally or externally.

Public sector

An LCA can be used to help make a decision or for educational purposes.

A student association can use the results of an LCA comparing disposable and reusable cups to organise a music festival. This will enable them to choose the solution with the lowest environmental impact.

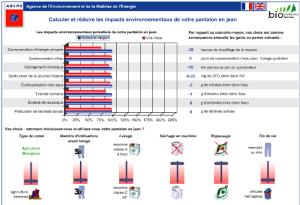

The results of an LCA can also be used to induce a change in behaviour (see the example of denim trousers).

Exemple : Life Cycle Assessment for a jean pants

ADEME commissioned BIO Intelligence Service to carry out an LCA of a pair of denim trousers. The report states that ‘the aim of the study is to produce an educational case study illustrating the consequences of our consumption choices’. For example, the results show the environmental impact of ironing trousers in relation to their life cycle.

The full report (french) is available here available here [pdf].

Private sector

External use

The main external use of life cycle analyses is for communication. In particular, manufacturers will use the results to translate them into advertising. They can also be used to construct Type III environmental declarations (ISO 14025:2006).

Internal use

When a manufacturer carries out an in-house life cycle assessment, it can have a number of objectives: understanding its products, guiding design choices, etc.

An LCA provides a better understanding, from an environmental point of view but not only, of its products or services and its production tools. Carrying out an LCA requires the collection of a certain amount of data that is not always known, or at least not all of it. Manufacturers can also carry out LCAs to compare their products with those of competitors in order to identify competitive advantages.

LCA can also be used to guide design choices. It provides manufacturers with an environmental perspective during the design process. They can compare materials, manufacturing processes, logistics organisations, etc. LCA is a tool that can be used as part of an eco-design approach.

What are the boundaries of the study? What life cycles are studied?

Boundaries of the study

In this first stage of the LCA, we need to consider the boundaries of the study, i.e. define the scope of the study and the level of detail used.

Should we take into account the construction of the factory used for production? The impact of the cars driven by the plant's employees? And so on.

Exclusion criteria can be applied. These can be based on mass or energy. For example, elements representing less than 1% of the total mass of the product are not taken into account, etc.

These exclusion rules depend on the sector of activity, the type of product or the expertise of the person carrying out the LCA.

Attention :

A small quantity of a substance can have a significant environmental impact. It is therefore important to check these criteria against the results of the LCA.

A sum of negligence is not necessarily negligible!

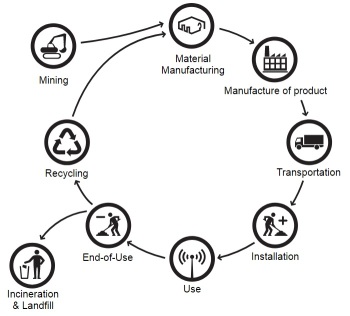

Life cycles studied

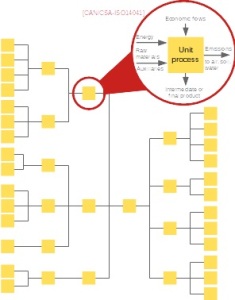

This involves modelling the life cycle of the product or service being studied. The elements considered, their quantity, etc., can be represented right down to the elementary stages.

What environmental indicators are taken into account?

The choice of environmental indicators should be made at the beginning of the study. In practice, this involves deciding which assessment method will be used in the LCA.

What products or services are we looking at?

In a life cycle assessment, products are never compared directly with each other. The comparison is made under the guise of a single functional unit between the reference flows required to achieve it.

What is the purpose of the functional unit and the reference flow?

Functional unit

ISO 14040 defines the functional unit as ‘a quantified performance of a product system intended to be used as a reference unit in a life cycle assessment’.

The functional unit (FU) thus reflects the service provided by the product or service under study.

Reference flow

ISO 14040 defines the reference flow as ‘the measure of process outputs, (...), required to fulfil the function as expressed by the functional unit.’

The reference flow (RF) is therefore what enables me to achieve the functional unit.

Exemple :

If I want to compare the environmental impact of a disposable razor and an electric razor, then :

The functional unit can be ‘providing a standard shave every morning for 1 month’.

The reference flow

for the disposable razor will be ‘a number of razors’ but also ‘a quantity of shaving foam and water’ needed for rinsing.

for an electric shaver will be ‘a fraction of the appliance and a quantity of electricity’ required to ensure functional unity.